Bolsover District Council, in partnership with Coal Authority, D2N2 (Local Economic Partnership) and University of Derby looked at exploring the potential of mine water energy to heat and cool existing housing stock and future homes.

At a glance

Housing Advisers Programme case study

2021/22 cohort

Executive summary

This project explored the feasibility of using a closed loop system to exploit mine water energy, which would significantly de-risk the use of geothermal energy and provide better co-efficiency than air source heat pumps to assist decarbonisation of existing housing stock and accelerate delivery of viable energy efficient future homes.

However, the costs and risks involved with exploiting mine water energy had limited the potential use of this resource to large housing schemes. Current thinking suggests a scheme of 1500 houses or more would be needed to create a viable district heating scheme powered by mine water energy.

Our aim was to explore how a closed loop system could reduce costs and risk and open up the use of mine water energy for retrofit or smaller housing schemes to accelerate decarbonisation of existing housing stock and drive the delivery of high energy efficiency future homes on two identified sites.

If the project is successful then it will be scalable across any area with a legacy of coal mining but could be re-purposed to exploit geothermal energy in any body of water stored underground.

Therefore, our project could have significant implications for our transition to net zero and decarbonisation of housing at a local, regional and national level and on this basis we have been granted additional funding of £800,000 from the LEP to take this project forward.

Challenge and context

Bolsover District lies on the former coalfields alongside a number of neighbouring authorities in Derbyshire and Nottingham. This means there is a number of disused mining systems that are flooding now they are no longer pumped and typically this water is at warmer temperatures below ground that surface temperatures in winter and cooler during the summer.

We have seen examples of how this mine water energy has been captured but these examples demonstrate that the process of exploiting this energy can be high risk in terms of potential costs and viability and difficult operationally. The costs and risks attached to these systems mean that typically mine water energy would only be viable for large housing schemes of around 1500 houses or more.

These systems typically extract water from one part of the underground mine system and inject the used water back into the system in a different location to allow the water to be ‘reheated’ (system b -below). This system requires two sets of drilled holes which are done at risk of missing the water giving rise to large but abortive costs. The cost of drilling is expensive in its own right, around £2500 to £3000 per metre.

Operationally, these systems also require high levels of maintenance because of the salinity and other contaminants in the mine water. Abstraction of water are also gives rise to issues around the consenting regime, which are avoided by using a closed loop system.

A closed loop system avoids these problems by dropping a single thermal pipe down a single shaft – the pipe is looped and carries clean water, which is heated inside the pipe by the surrounding mine water.

However, this approach gives rise to a number of technical issues around the ability of the water in the shaft to recharge sufficiently to provide a consistent supply of energy and this may limit the usefulness of the approach if this problem limits the number of houses that can be served by the district heating solution.

What we did

We commissioned the University of Derby to work from an initial feasibility study carried out by the Coal Authority.

This was a highly technical piece of work and until we connected with the University we were unable to find a suitably qualified consultant to work on this project with us, which is the principal cause for the delay in completing our project.

The difference we made

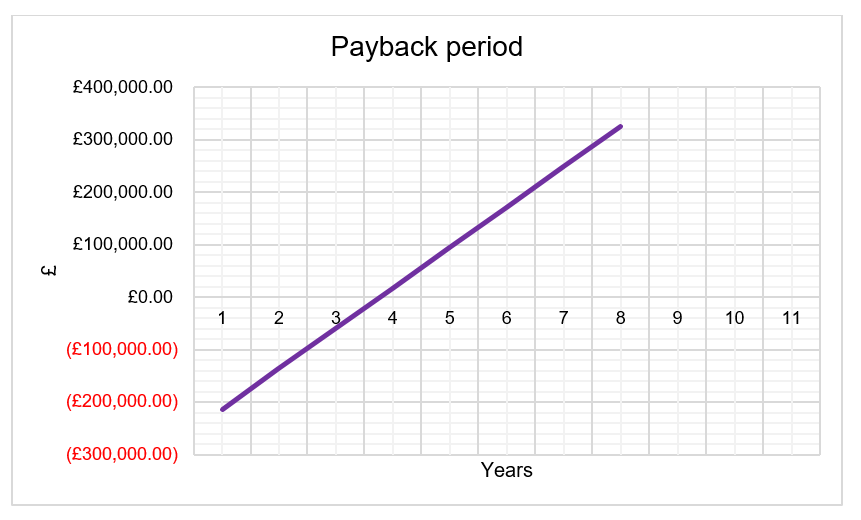

We found that a closed loop system to serve 100 homes could achieve payback within four years.

We found that we could save significant carbon savings through the closed loop system:

- Natural gas boiler carbon emission per year: 338,824

- Heat pump carbon emission per year: 55,583

- Total saving (kg Co2) per year: 283,241

At current energy costs, we found that there would be a significant cost saving on energy used:

- COP system: 4.86

- Heat pump operation: 12 hrs/day

- Heat pump peak: 400kW

- Heat pump peak energy output: 1,440,000 kWh/year

- GSHP system peak electricity demand: 80 kW

- GSHP system peak electricity consumption: 288,000 kWh/year

- Electricity cost: 34p/kWh

- Energy cost: £97,920 per year

Gas boiler heater operating costs can be calculated as:

- Heat demand: 1,440,000 kWh/year

- Efficiency of the boiler: 85%

- Actual gas required including the boiler efficiency: 1,694,118 kWh/year

- Gas tariff: £10.33 per kWh

- Total cost: £1,750,002 per year

When taken together, the results from our project are really promising and demonstrate that a closed loop system using mine water energy could be used at local level to heat and cool future homes in at least two separate locations in our district.

What's next

The next step is to use funding from the LEP to build a demonstrator to test the real life performance of the system to test the outcomes from the academic work. If this is successful, we are then going to work with the house builders on the nearby site to create a cluster of future homes connected to a district heating system powered by water to demonstrate proof of concept.

Lessons learned

The key lesson learned is that we proposed the production of an ‘easy’ guide to mine water energy but we have deferred this part of project because our experience if that the principle of using mine water energy is easy to explain but we’re are still exploring how to simplify the process of calculating the thermal properties of the shaft and the properties of the underground water especially in terms of calculating flow rates and how the energy recharges.

This process is critical to the viability of the scheme but we are concerned that the level of expertise required to complete this process and the time it has taken to complete would be a barrier to a wider take up of geothermal energy especially noting that we need to build a demonstrator to test the real life performance of the system.

Therefore, we aim to present further findings from our project once the demonstrator has been completed and the results from the demonstrator have been verified.

Contact

Chris Fridlington, Assistant Director for Development, Bolsover District Council: [email protected]